Paul’s pain in the RS!

Having owned his Mitsubishi Lancer Evo 8 RS for seven years, you would think that Paul would have a plethora of stories to tell of adventurous times slaying his local B-roads in Wales, but sometimes things don’t quite go to plan.

Let’s rewind seven years. Paul imported his RS as a standard car, albeit clad in some questionable graphics. Paul swiftly de-stickered the suspect decals and enjoyed the Evo for a while before the desire for more power took over. The Evo RS models are very special cars from the factory – designed to be converted to competition cars, they are lighter than the more common GSR and with a more aggressive differential setup. But still, nobody can complain about having a bit more performance!

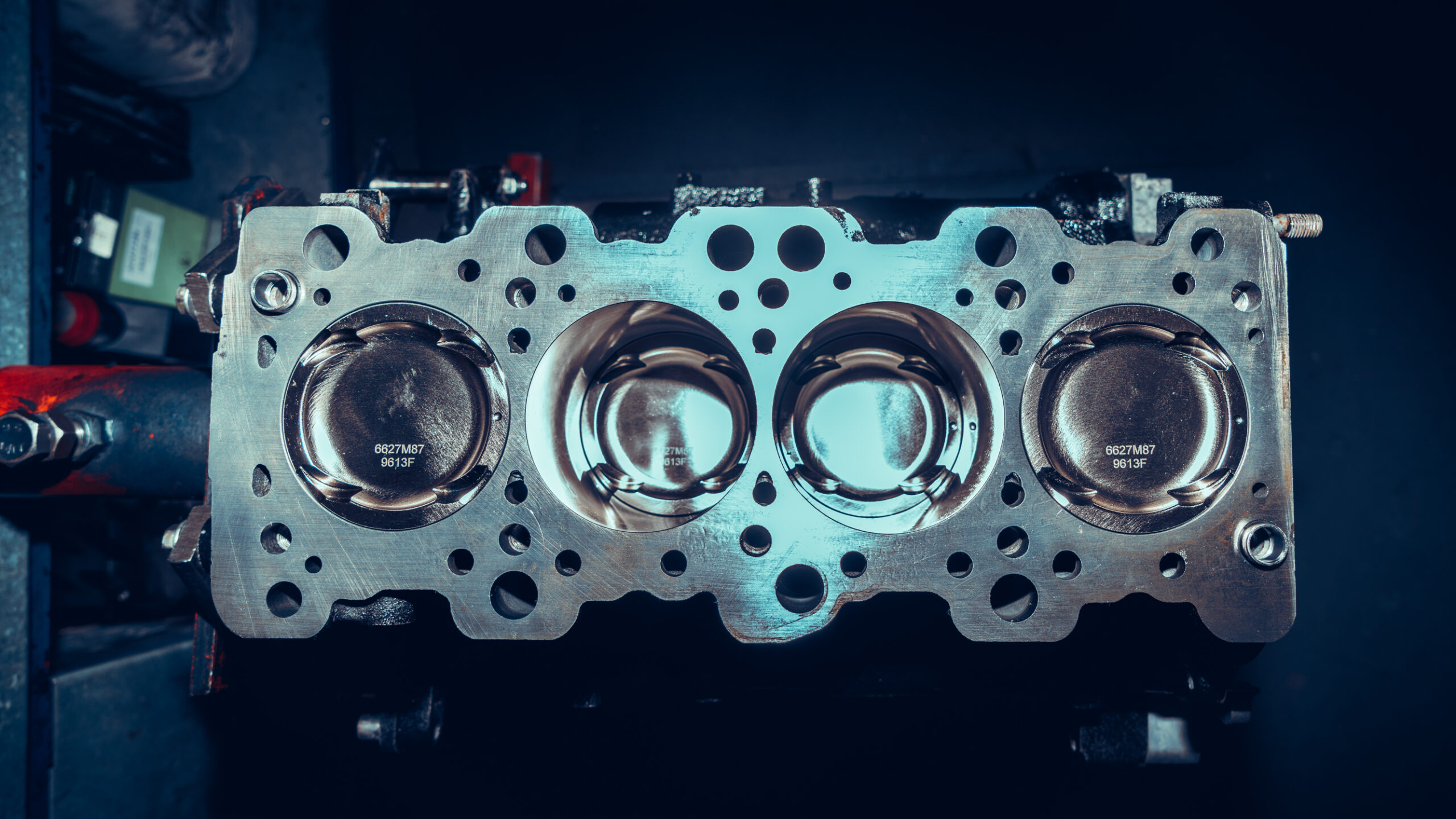

Lusting for increased horsepower while staying safe, Paul sent the Evo off to a local tuner for a ‘rod job’ (uprated rods in an otherwise a stock engine). After a prolonged period, Paul got the call to say the car was ready for collection. Not even 1000 miles later, Paul’s Evo fun ended abruptly – a melted piston!

Fast forward a while later and more frustration with delayed progress on the rebuild. Paul lost all faith with the garage he was using and started researching tuners that could get his car back on track and back to its very best. A conversation with our Alan happened and the rest is history. With the car shipped to ET HQ for recommissioning, things were on the up.

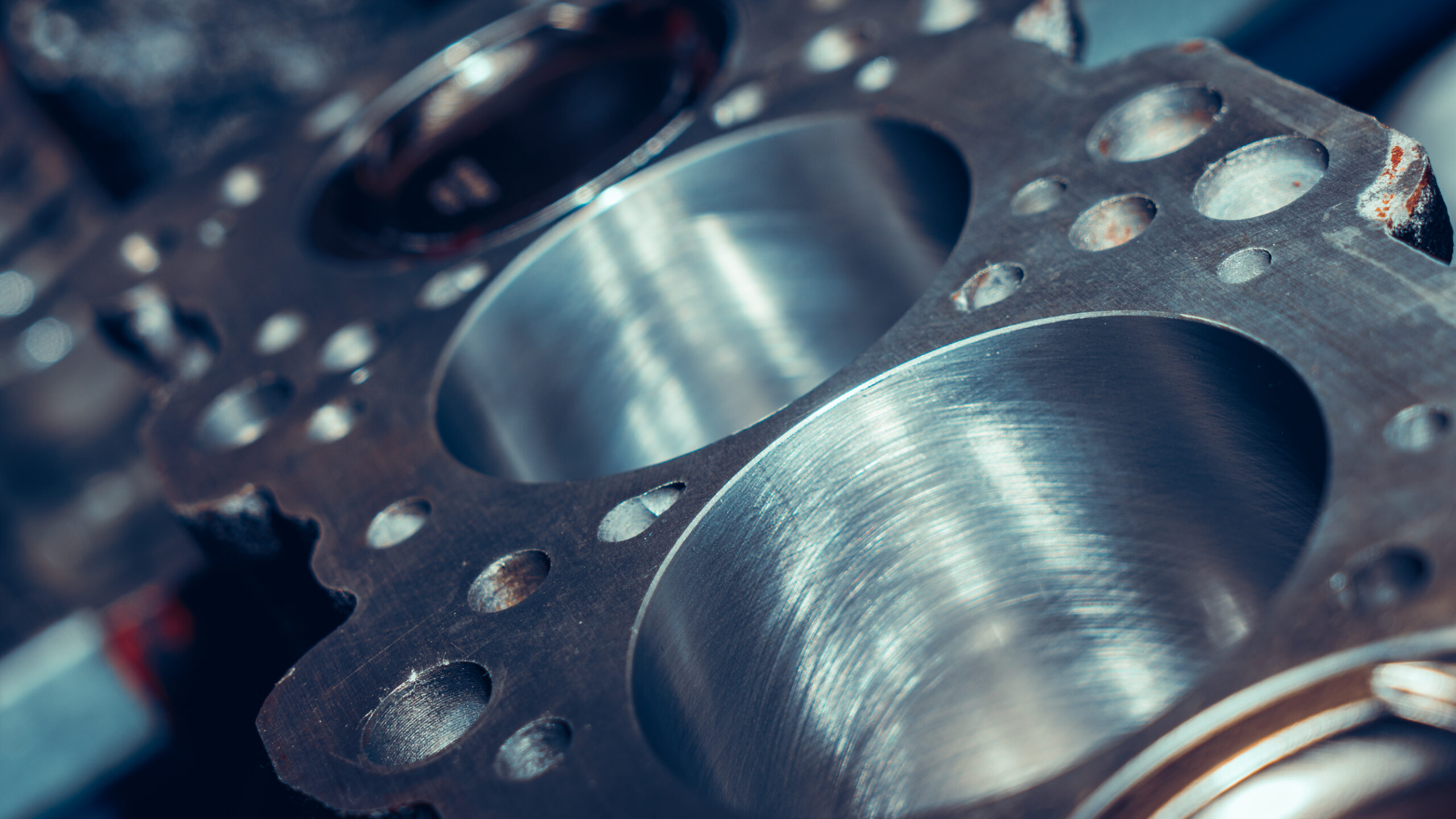

Tasked with assessing the current state of Paul’s RS, the Enginetuner team completed a comprehensive report of all the issues. With Paul updated, the next course of action was to dive into the engine. Initial investigation identified that the compression ratio was far too high for a forced induction engine.

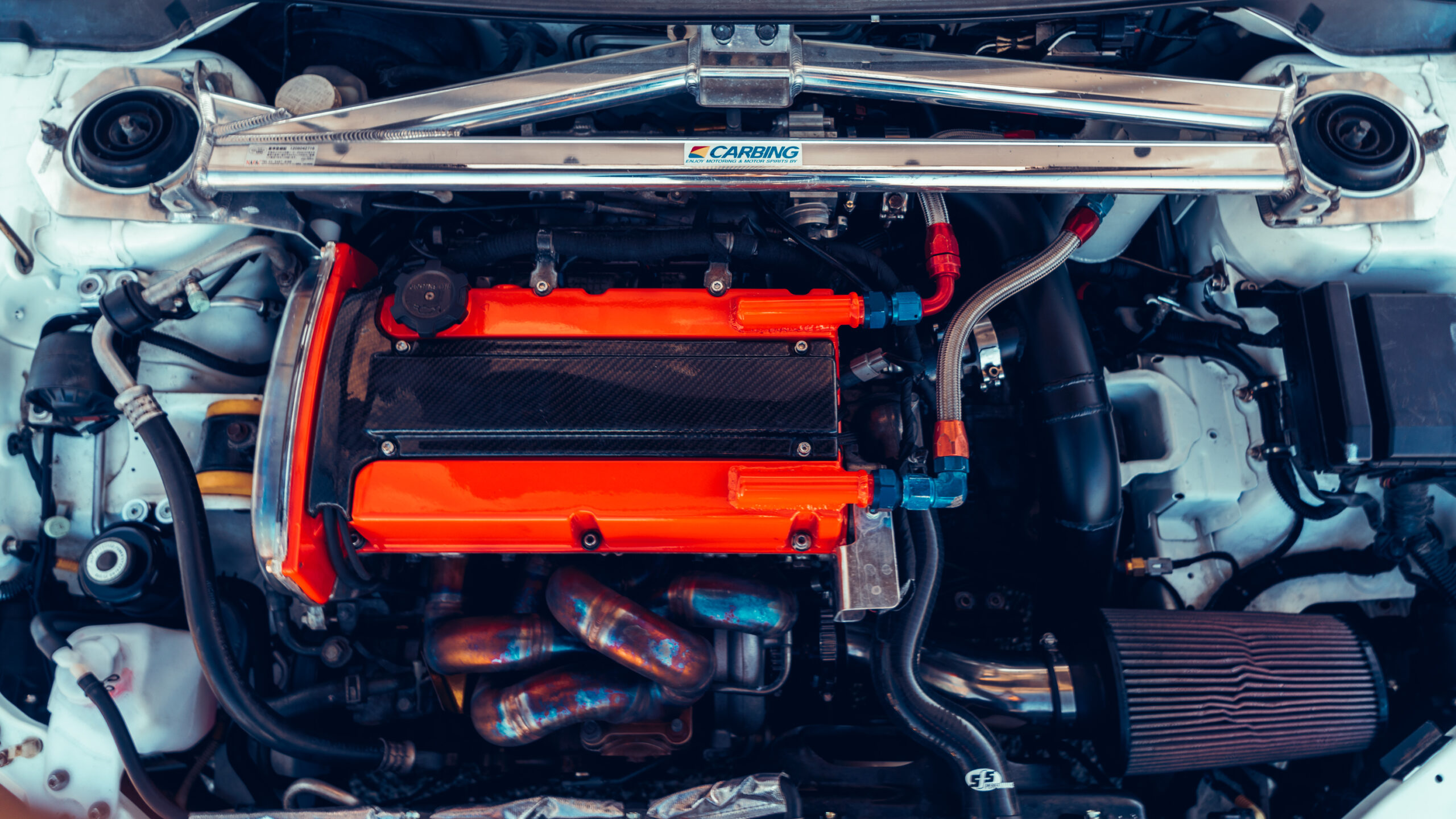

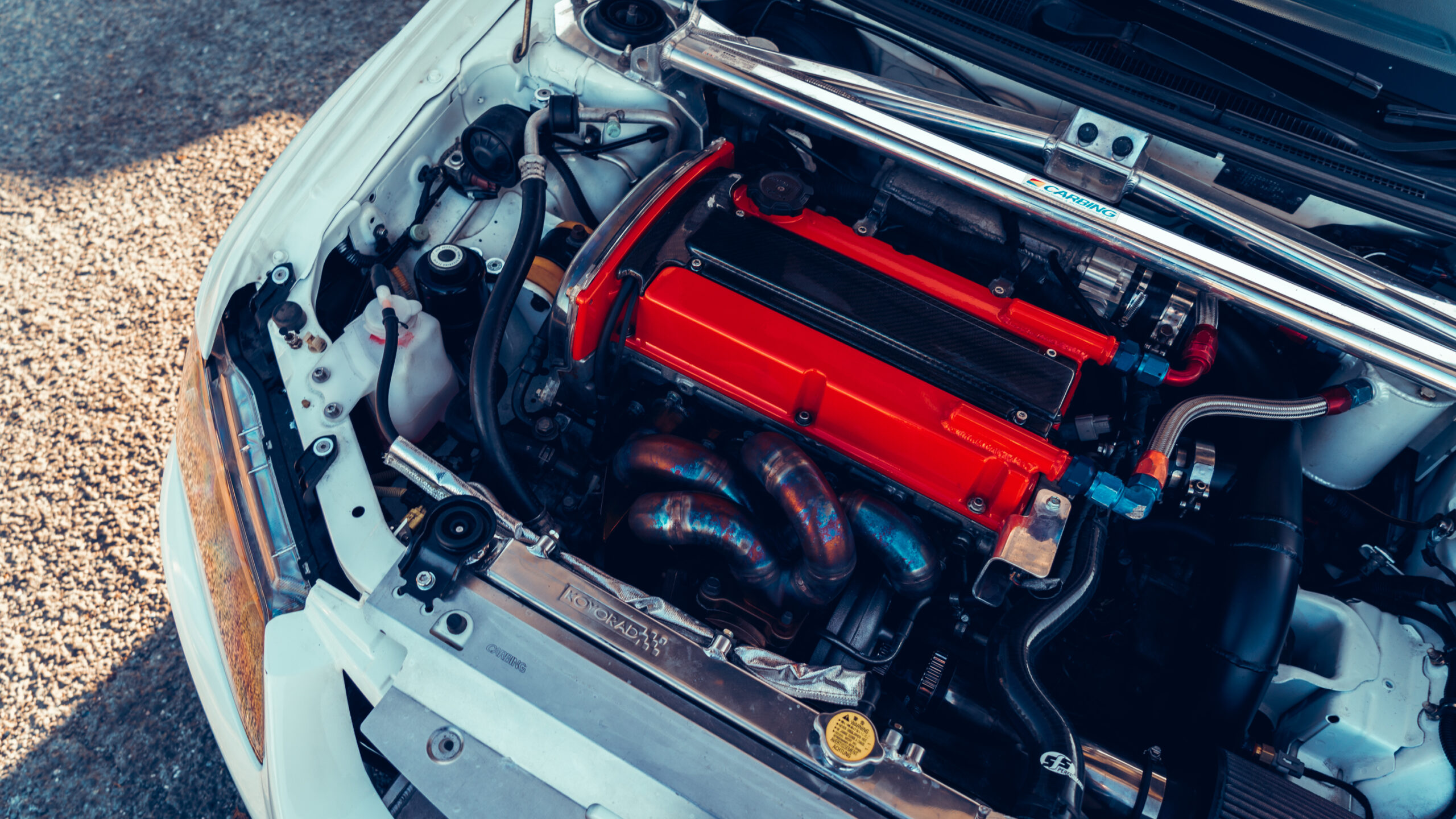

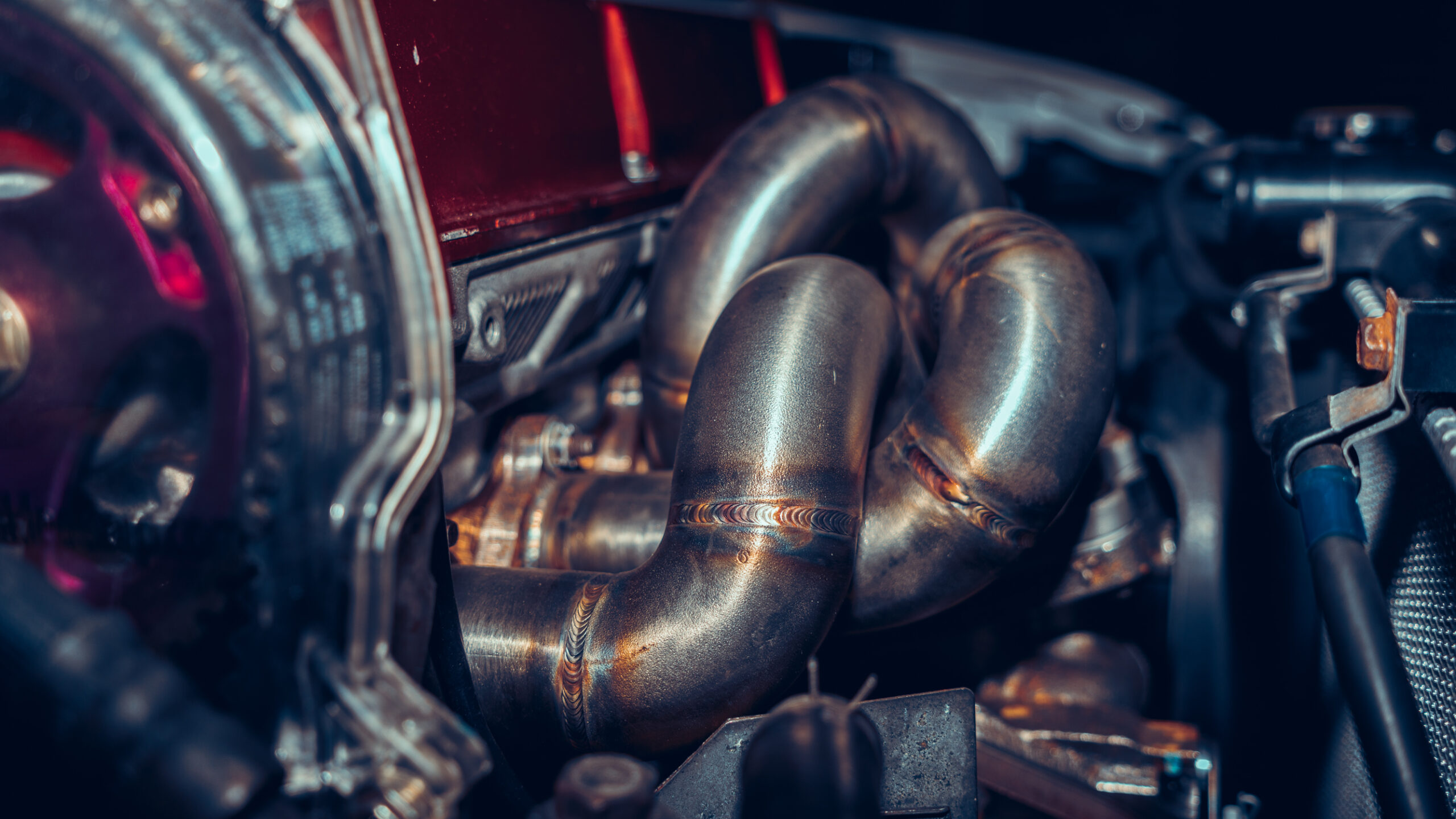

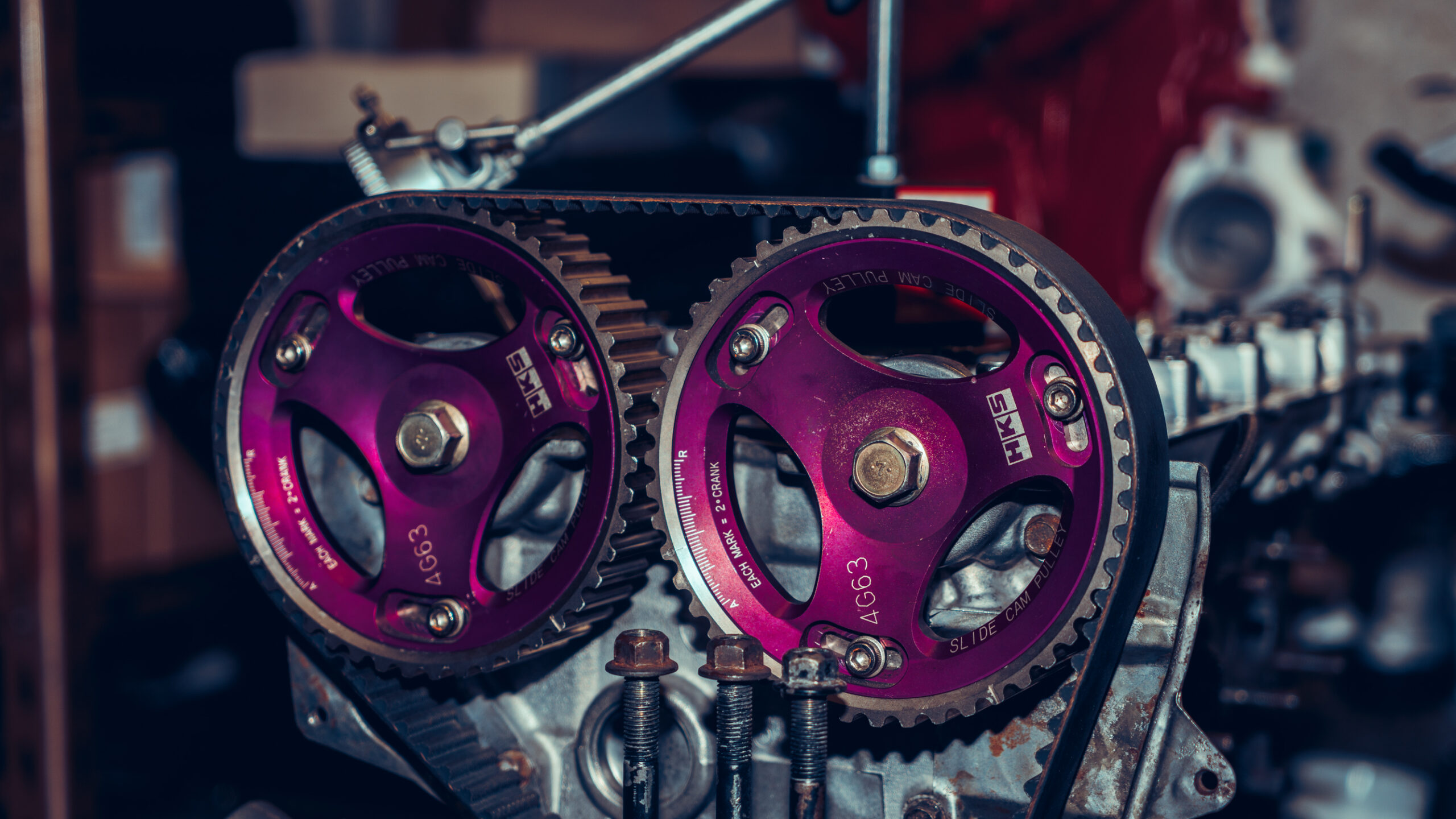

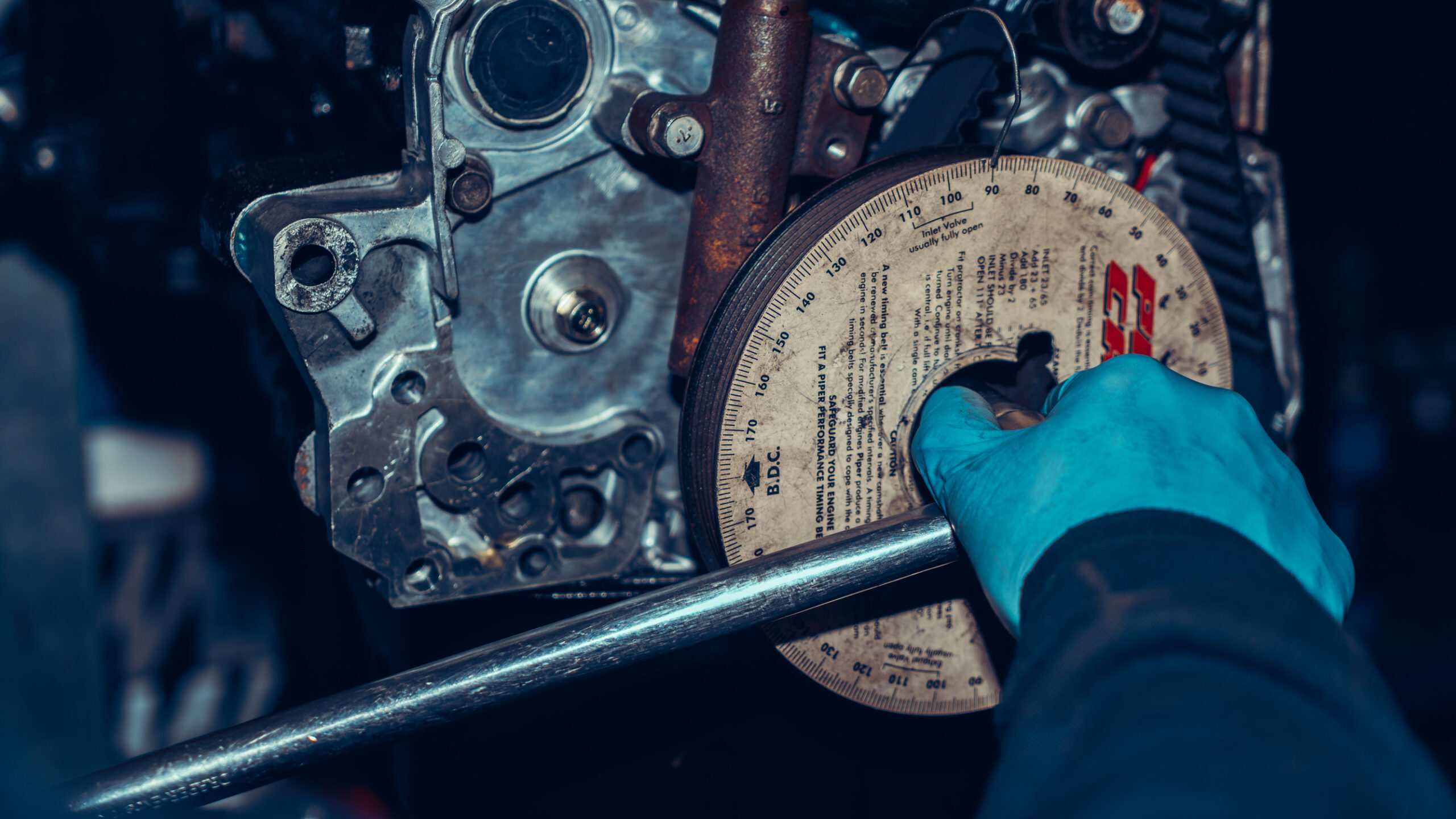

With Paul giving us the go ahead to rebuild the engine, chief engineer Andy rebuilt the block and the head and fitted 272 camshafts, forged pistons, new gaskets, belts, and much more. This time, the correct compression ratio was achieved thanks to Andy’s decades of experience. While the engine was out, we powder coated the rocker cover to add some much needed flavour to the engine bay.

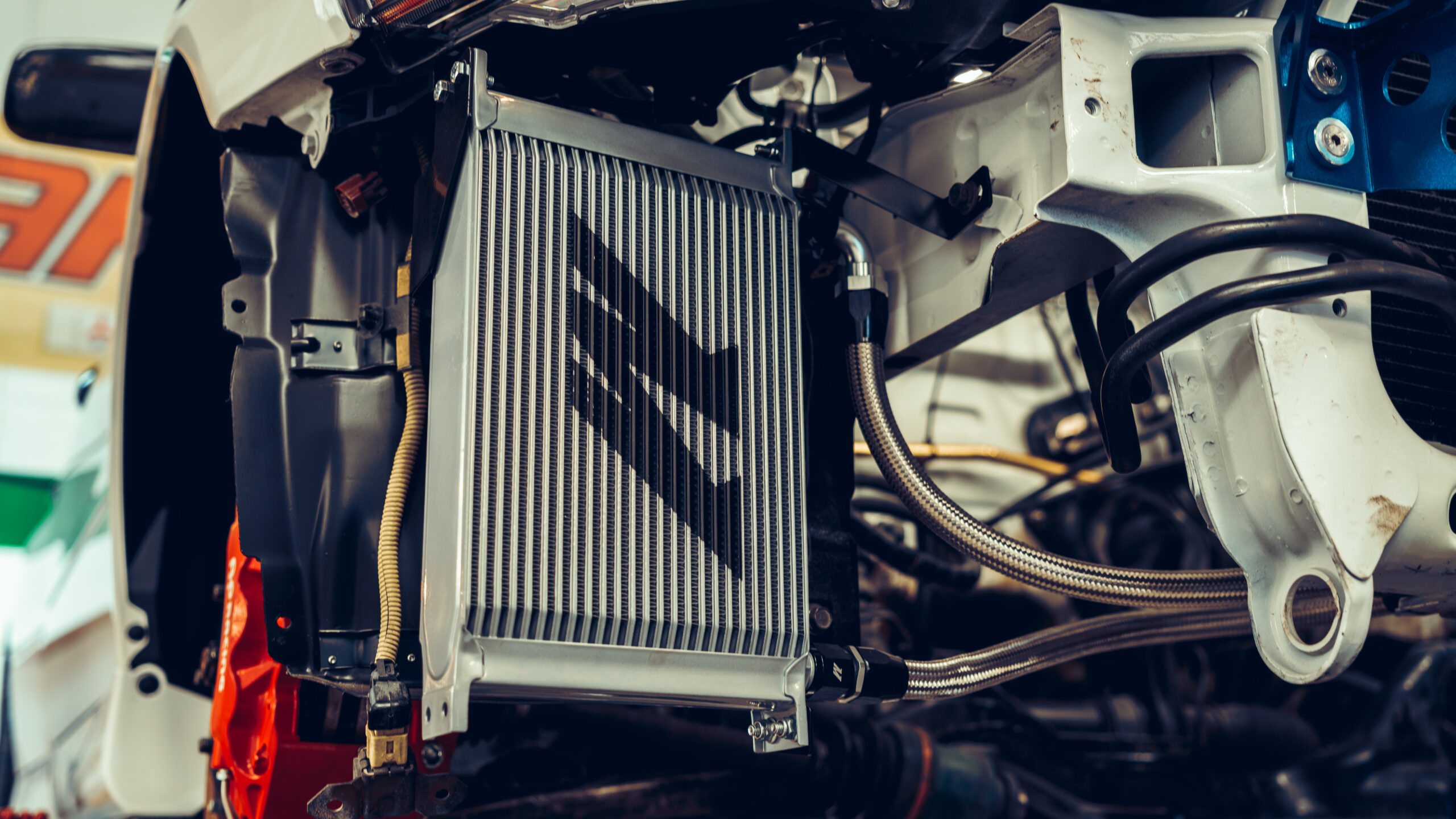

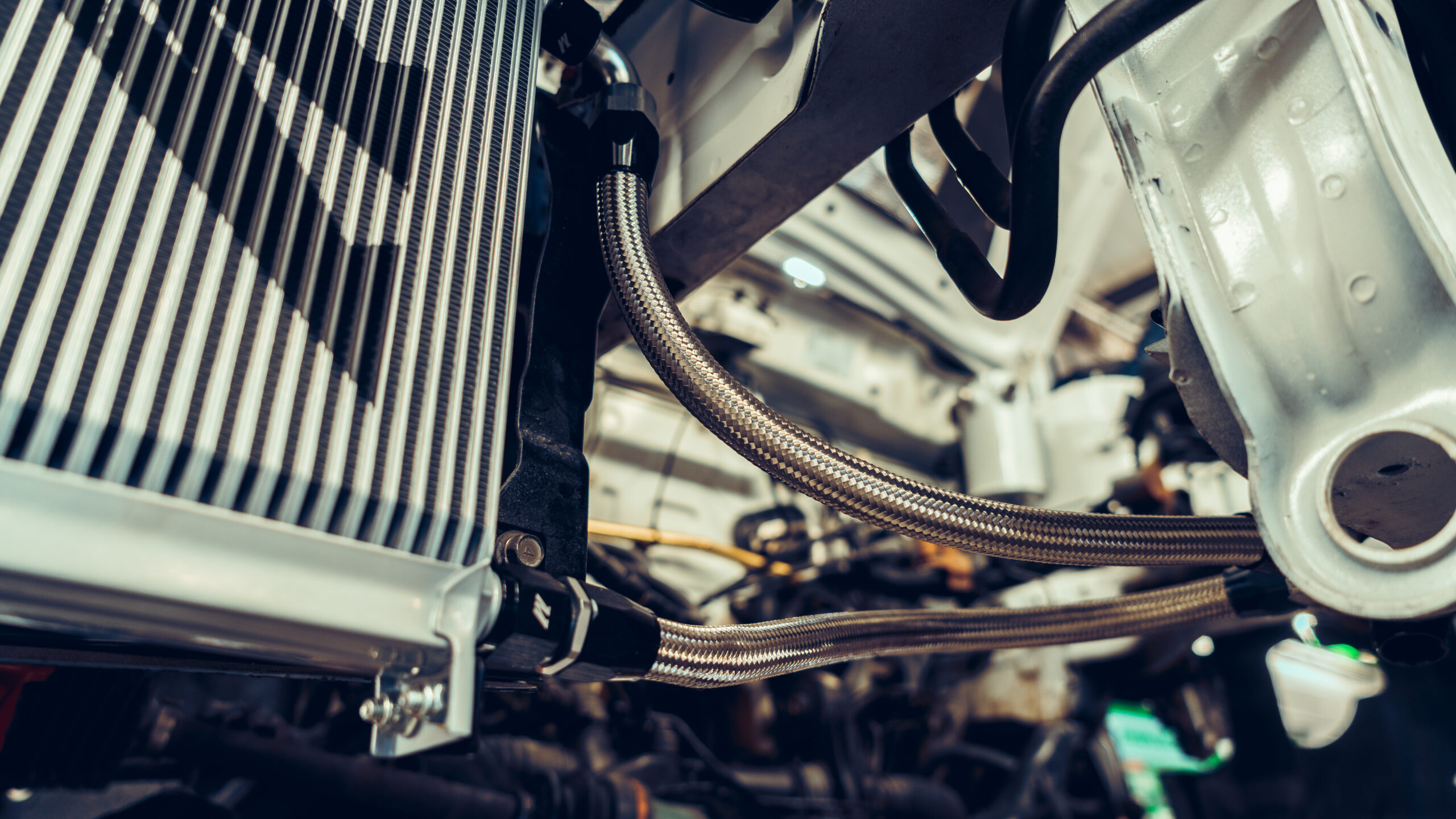

Over to the technicians who reinstalled all the necessary hardware before fitting the engine back into the bay. To keep things cool we added a Koyo aluminium radiator and our fabricators modified the custom front mount intercooler to fit the vehicle properly. With the supporting mods now in place and a myriad of further issues rectified, we turned our attention to the wiring for the Link ECU along with upgrading the fuel system to cope with the power that the engine was now able to cope with. Once running well, the team used Enginetuner’s state of the art laser alignment rig to set the Evo’s suspension geometry.

Then it was Martyn’s turn to build a bespoke base map to allow Paul to complete the mandatory 1000 mile running-in period before returning to ET to turn the power up! A fresh 12 month MOT and oil service saw the vehicle ready for Paul to collect from ET HQ.

From remapping to full engine overhauls, Enginetuner can help. We prevail where others fail!

Check out our website for more information on some of the special builds we have recently completed.

Enginetuner – Performance engineering at its finest!